Table of Contents

The challenge

Our client needed to strengthen their supply chain of chromatography resin production while ensuring a high-quality product.

100%

accurate replication of the chromatography resin at the new site

Our teams had one major challenge: How do you bring a product to a new facility, and continent, and ensure it remains 100% identical to its European counterpart?

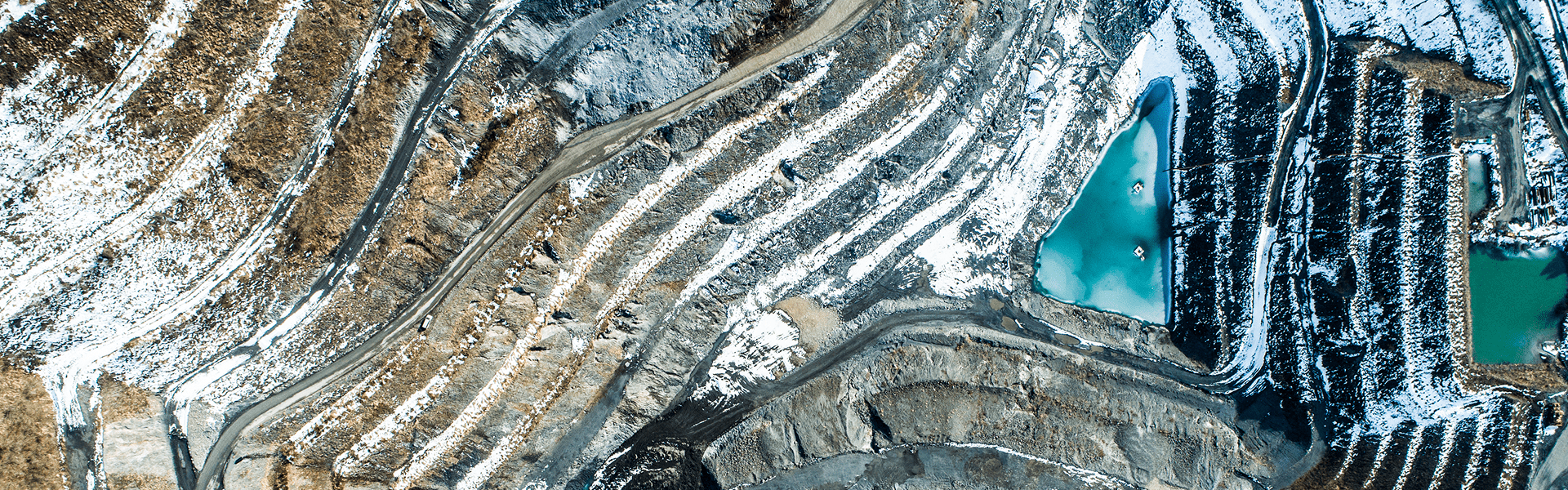

The plans for the new site were ambitious. The new campus would be extensive, uniting production, storage and administrative facilities onto a single site. Initial plans were drawn up for a concept design, based on an idealized, hypothetical greenfield (unused land) site. After consideration of the associated costs - financial, social and environmental - the client agreed that a change of plan was necessary. An existing 400-acre brownfield (used land) site was identified that previously housed another facility, and Arcadis' challenge was to descope and reimagine the facility within the available space. The design needed to incorporate the key functionality of the initial ambitious concept, and fit the size, shape and existing infrastructure of the new location.

Having never produced its product outside the EU, there was a learning curve for the client and for our teams that extended beyond design and construction. The team had to work together to create new standards for production and translate the process into English for the first time to meet the US regulations and standards.

The solution

Arcadis assembled a best-in-class team to support the design and engineering of a new 40-acre campus.

40

acre footprint for the campus, on an existing 400-acre site

The Arcadis team - initially spread across the US and Ireland- collaborated asynchronously to bring the right expertise at the right time. Projects, tasks and ways of working across the project were optimized to meet the clients' needs, ensuring visibility, assurance and constant communication.

As needs scaled up and the project progressed, the Arcadis team scaled too. A multi-disciplinary team incorporating architectural design and full-service engineering (including all relevant disciplines) came together to partner with the client throughout the project lifecycle. More than 150 people had joined the project as we entered the construction phase.

Thankfully, the team wasn't starting from scratch as there was an existing facility in Europe to use as a blueprint. They partnered with the engineers of the client's first site, using the original specifications and drawings as inspiration and guidance to ensure symmetry in vital processes and manufacturing stages.

Collaboration and communication were aided by digital technology, with the BIM modeling from the detailed design phase not only supporting decision making, but also engaging colleagues across the client organization, sharing the vision for the new campus.

The impact

When complete, the campus will broaden and secure access to life-improving and life-saving technology.

150

Arcadians working on the project simultaneously, collaborating seamlessly across multiple countries and disciplines

When complete, this project will significantly bolster the production of these crucial resins, broadening and securing access to life-improving and life-saving technologies in the making of therapies.

The selection of an existing brownfield site was also significant. By retrofitting existing buildings and tapping into existing utility infrastructure, the projects' embodied carbon footprint was significantly reduced versus the initial greenfield plan. Furthermore, reactivating a dormant site will also revitalize the local community, creating new jobs, and bringing economic and social improvements.

Not done reading?

This also might be interesting for you

- Related Projects

- Related Insights

- Related Blogs