Table of Contents

The challenge

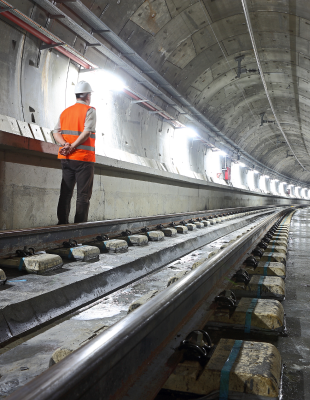

As one of the oldest and largest wastewater treatment works in Europe, Davyhulme was ready for modernization. But it needed to happen while keeping the plant fully operational.

1.2 million

Having access to clean, safe water is often something we take for granted. When we turn on our kitchen tap, how many of us stop to wonder about the journey our water has been on? Fortunately, wastewater treatment works – like Davyhulme, in the North West of England – are working tirelessly in the background, processing thousands of litres of water every second. But they need investment and maintenance to ensure they continue to operate at their best. And as one of the oldest and largest works in Europe, Davyhulme was ready for modernisation.

The solution

Working as part of a collaborative design and build team, we used innovative new techniques to achieve major time and cost savings and ensure a cleaner and greener treatment process.

5,569 litres

The Davyhulme Treatment Works is considered to be the site where modern wastewater treatment was invented more than 100 years ago, and it continues to be a place of pioneering sewage treatment processes.

Providing clean water to over one million people in the North West, the plant is a vital asset for the local community and surrounding environment. However, with the key primary and secondary treatment containers of Davyhulme dating back as far as the 1960s, it was less effective compared to modern treatment plants. The constant tightening of regulations, accompanied by population growth, presented a risk of further inefficiencies if improvements were not made.

-

READ MORE

Working as part of a collaborative design and build team, Arcadis, in a joint venture with Mott MacDonald, was appointed by Laing O’Rouke to help United Utilities modernise the plant.

In particular, as part of the National Environment Programme Davyhulme needed to be upgraded to improve the quality of treated waste. This involved constructing a new Activated Sludge Plant (ASP) and connected works, which were vital as the final emissions are discharged into the Manchester Ship Canal, which is designated under the Freshwater Fish Directive.

The design team were responsible for providing specialist engineering support for the upgrade. This included civil, structural, geotechnical and hydraulic design, using state-of-the-art Building Information Modelling (BIM) technology and Design for Manufacture and Assembly (DfMA) techniques to design a new process stream alongside the existing plant. This approach ensured that the existing works could remain operational throughout the construction period to avoid disruption to millions of users and the local environment.

The challenge for our design teams was to use new twin-wall technology, which comprises separate sewage and drainage systems, to create one of the biggest civil engineering water retaining structures in Europe. We had to do this at the same time as accommodating all the factory constraints, including limited panel sizes and section depths, without compromising design compliance.

We designed the pre-cast units in a BIM environment, using software compatible with United Utilities systems to allow direct import/export into their process system for component construction. Over 2000 pre-cast elements, including twin-wall panels, tie-beams, walkways, lattice panels and post-tensioned tank panels were used to construct the main process aeration tank. This resulted in a unique hybrid design of a precast/in- situ concrete structure, which pushed the boundaries of DfMA innovation and resulted in substantial programme and cost savings for United Utilities.

The impact

Davyhulme will continue to provide safe, clean water for over one million people across the North West and is a vital asset for the local community and surrounding environment.

2,000

Long term reliability

The modernisation of Davyhulme saw previously abandoned land put to good use in the construction of six circular primary settlement tanks and a new Activated Sludge Plant with ten circular final settlement tanks.

This work provided a huge environmental benefit for the site, improving outflow and subsequently the quality of water entering the Manchester Ship Canal. Thanks to the use of the latest technology and the use of pre-cast elements, we have been able to ensure a cleaner and greener treatment process, the new and extended treatment works has brought increased reliability at reduced operating costs, ensuring that Davyhulme is capable of meeting the long-term demands of the Manchester and Northern Powerhouse area it serves.

Not done reading?

This also might be interesting for you

- Related Projects

- Related Insights

- Related Blogs