Table of Contents

The challenge

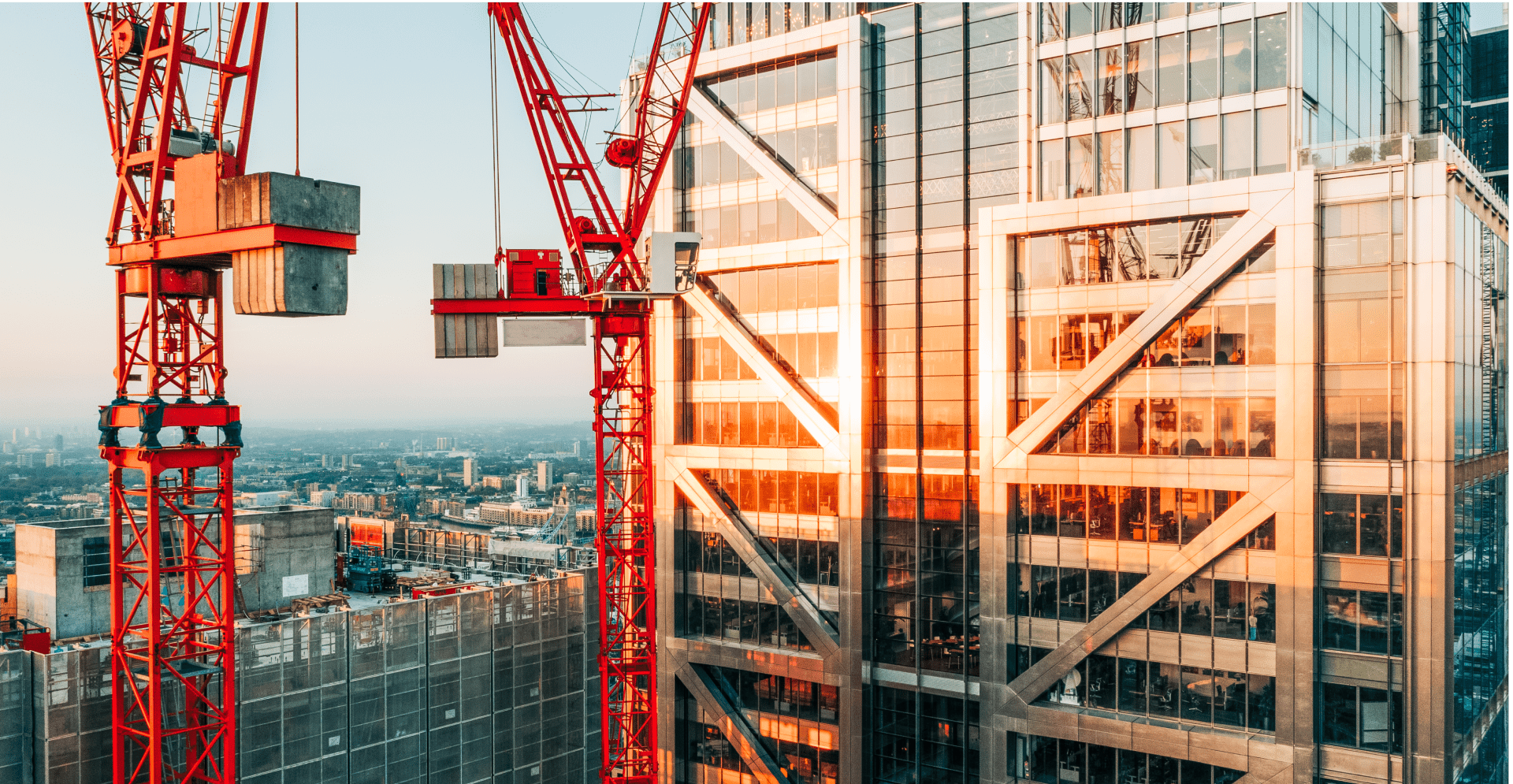

Retooling the Oakville site to transform the Oakville Assembly Complex into a Canadian hub of electric vehicle manufacturing.

$1.8

billion project value

The 487-acre Oakville site included three body shops, one paint building, and one assembly building. The campus was planned to become a high-volume manufacturing hub for North American EV production. A Major challenge was that several components of the Ford OAC’s infrastructure have been aging (built circa 1953) and thus was not compatible with the proposed infrastructure.

The solution

Architectural and engineering to carry out the multidisciplinary design of the repurposing effort to meet the requirements of the new operations.

The new modernization program proposed new layouts and equipment that required restructuring and upgrading of several parts of the existing complex’s facilities.

Arcadis was engaged as the primary AE consultant to provide engineering solutions to upgrade the existing complex to accommodate the new program requirements.

Arcadis initially performed engineering studies spanning several disciplines to develop concept solutions, identify areas of code deviations, and establish the scope for detailed design.

The impact

Arcadis proceeded to successfully develop the design plans to retool the existing facilities under strict timelines to meet the program schedule.

After the initial study phase Arcadis proceeded to successfully develop the design plans to retool the existing facilities under strict timelines to meet the program schedule. The construction phase was also supported by Arcadis up to the middle of 2024.

Ford (Mid 2024) shifted focus to another program on site and Arcadis is assisting to establish the new design and construction requirements.

Explore Our Engineering Expertise – Contact Arcadis Today!

Not done reading?

This also might be interesting for you

- Related Projects

- Related Insights

- Related Blogs