With the rise of fast-track treatments and vaccines, we explore how to expedite the engineering, procurement, construction, management, and validation (EPCMV) process for life sciences facilities.

The new meaning of “fast”

Pandemic-related viruses have caused the life sciences industry to fast-track treatments, including vaccines. This is a noble pursuit, but there’s no point in rushing if it then takes the typical duration to design, construct, commission, qualify, and validate a manufacturing facility. We will have lost the momentum of this valiant effort.

Fortunately, the tremendous ongoing efforts by hundreds of life sciences companies are supported by the architecture, engineering, and construction (A/E/C) industry, which is applying an expedited engineering, procurement, construction management, and validation (EPCMV) approach to help deliver licensed facilities more quickly.

What Arcadis is doing differently to help our clients fast track these critical projects

Our experience of delivering licensed facilities in the United States has led to the following key concepts that pharmaceutical manufacturers will want to consider when working with an experienced EPCMV partner on a project that needs expedited delivery:

The tremendous ongoing efforts by hundreds of life sciences companies are supported by the US industry, which is applying an expedited EPCMV approach to help deliver licensed facilities more quickly.

Begin conceptual design early

Don’t wait until you are in late-stage clinical trials with a molecule to begin facility layouts and process flow diagrams for the manufacturing process. Getting a head start on these conceptual designs will help develop early cost estimates, determine available schedule options and critical path activities, and identify the technology that can be deployed fastest. Beginning conceptual design early involves little risk and can gain weeks or months on your timeline.

-

Read more

Having said that, we have seen clients make the mistake of skipping the conceptual design step altogether, with the hope to save time. The conceptual design effort charts your course and helps prevent going in the wrong direction.

There are times when a company has a promising molecule but doesn’t yet have clinical data. In such a case, we start conceptual design early. This allows us to design and assess the layout of equipment, determine general timelines and expected milestones, and build an estimate of costs. Early process concepts helped inform the process scale-up/-out for large-scale manufacturing of the molecule. Starting the early phases of engineering before clinical results ensures we hit the ground running once the results of early-stage clinical testing are known and favourable.

Perform steps in parallel and stack your schedule

Some design, construction, and commissioning activities, which are traditionally performed sequentially, can in fact be done in parallel by making educated decisions early. It requires considering how much to vertically stack your schedule that would otherwise be executed linearly. For example, overlapping final detailed design elements with some of the early construction activities (e.g., procurement of long-lead items and construction enabling works) and early CQV (e.g., identifying system boundaries and creating commissioning and validation plans) can gain quite a lot of time. This does require detailed planning and dedicated resources.

-

Read more

Consider our earlier example of a project that overlapped conceptual design with clinical studies for a vaccine. There were other activities we were also able to stack. Before preliminary engineering was complete, we brought in procurement and released construction on enabling works packages. While early construction activities were underway, we overlapped the final design. This way, when the design was complete and issued for construction, the construction manager was already aware of the project scope and was able to line up the next steps of equipment and material buyout, as well as line up the building trades.

Likewise, toward the end of the construction phase when the project was substantially complete, we overlapped producing engineering punch lists for construction with the CQV team executing I/OQ protocols.

Separate design of the process from obtaining a shell that will house it

Another example of how we stack activities to go faster is to build out or source the facility before knowing the final interior process space requirements. First, we work with the client to block out, in general terms, the area they will need for their new process. From there, we can estimate the total facility area requirements to include all ancillary and support spaces. During this blocking process, we also work through plans for growth, expansion, and future buildout.

-

read more

With an estimated total facility size in mind, the client can begin to evaluate where their new process will be housed. They could start a market search for an existing facility appropriately sized to house the process with the necessary utilities, clear height, and other requirements. In some regions of the country, there is a tremendous amount of space available to lease that could be repurposed, thus avoiding a more costly and time-consuming greenfield approach.

The client might also consider at this time whether they can renovate an existing space they already occupy or even start down the path of constructing a new greenfield facility if that is deemed necessary or desired. The point is, establishing the size needed for the process allows the facility design to move forward in parallel with a design of the interior fit-up. Thus, the overall time to market for the molecule can be reduced.

Take calculated, educated risks

These decisions require a willingness to take calculated risks early in the process based on educated assumptions about several factors, including:

Greenfield, Brownfield, or CMO?

Whether to build a greenfield project, retrofit an existing facility, or outsource to a Contract Manufacturing Organization (CMO) is a question we are often asked. In the instance of an extremely fast-tracked project, a facility location decision can be influenced by staffing and tech transfer. So, retrofitting existing space, if available, is a favourable option.

-

read more

This type of decision will also depend on the technology platform being used to produce a vaccine. Retrofitting an existing facility could be ideal to supplement the production of a novel therapeutic vaccine platform, for which the drug substance volumes are relatively small owing to their high potency. On the other hand, for cell culture-based vaccines, the larger volumes may require building a new facility—you’re just not going to easily find a 200,000-square foot facility that can be repurposed.

For large-volume processing, it can make sense to outsource to a CMO, but this is not always a straightforward decision. A company typically hands off a fully developed process to a CMO, simply contracting its space and labour expertise. But in the case where a client is still developing or scaling up/out the process, handing it off to a CMO simultaneously may require a CMO flexible enough to adapt their processes and procedures to meet those of the client. There are many CMOs capable of this, but it is a new way of working together that needs to be considered. Also, partnering with a CMO means sharing technology and IP that a company might not otherwise want to share.

A company may choose to spread the risk by doing both: they might build in a facility they own and, in parallel, design and construct the process in a CMO facility. The speed at which the industry is currently moving to develop these vaccines means that the technology transfer is being done differently than it has been traditionally.

Applying a Lean project delivery model speeds up EPCMV

Lean is the fastest, most effective, and safest way to deliver projects. Projects that have a high-intensity Lean focus are three times more likely to finish ahead of schedule and twice as likely to finish under budget than traditional projects.1 Lean is based on collaboration between engineering design and construction management and reduces the redundancy and waste that occur in traditional executions. We commonly use several Lean principles on project work regardless of whether the project is following this method of delivery.

1 Lean Construction Institute. "Lean Projects Are Three Times More Likely To Complete Ahead Of Schedule According To Dodge Data & Analytics' Research." 22 December 2016.

Below are some Lean methods that can expedite project delivery on any project, particularly during a pandemic climate:

-

Pull planning

Using this mechanism allows all construction and design trades working side-by-side to collaboratively establish a milestone schedule at kick-off, including engineering, procurement, construction, commissioning, and validation. This type of planning approach adds accountability to the team members doing the work and outlines key deliverables for the following 3–4 months.

-

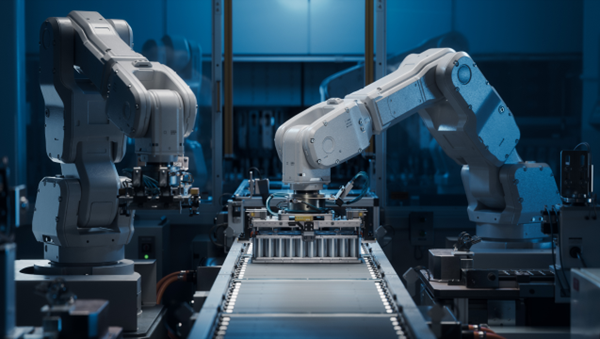

Modular design and execution

Doing more work offsite can fast-track projects by reducing craft staffing at the job site.

-

Integrated project delivery (IPD)

Selecting vendors early and using their expertise in the design phase improves constructability, execution, planning, and cost estimating.

-

Conditions of Satisfaction (CoS)

Having the team agree on the project’s overall CoS early ensures the project team is aligned with the client’s needs and can apply them to every decision.

-

The Big Room

We typically create a collective workspace where everybody—engineering, procurement, design, contractors, clients—can meet face to face. This fosters open collaboration and team synergy and leads to staying on schedule, minimizing cost, and delivering a safe and constructible facility. During the pandemic, we have modified this practice to a virtual Big Room. On some projects, we have scheduled hour-long calls for every evening, Monday through Saturday. There is no such thing as too much collaboration and communication.

-

Building Information Modelling (BIM) and Virtual Design Construction (VDC)

We use BIM and VDC to enhance collaboration, reduce rework, and improve constructability and clash detection. BIM reduces redundancy of effort between design and construction by providing, for example, 3D models to contractors in the field.

Procure long-lead equipment during the early/conceptual design phase

Since obtaining specialized process equipment is typically the longest lead item during EPCMV, making educated assumptions about the type, size, and utility requirements of the equipment that needs to be ordered will speed up project delivery.

-

read more

We can start an equipment list, especially for long-lead items, roughly around the same time that we first estimate our client’s square footage requirements, for example, during the initial programming phase. Clients usually have a good idea of their primary process equipment needs and we categorize these early into an equipment list to establish a procurement plan.

This plan feeds directly into the overall project timeline. We identify purchase lead times for each item, which informs an integrated project schedule and identifies when they buy equipment to meet the end date of construction. Starting the procurement process early will allow for joining long-lead equipment vendor production queues before the final lock-down of equipment size and features. This occurs while the facility design is underway.

Include Commissioning, Qualification, and Validation (CQV) from the beginning

The endgame of any CQV effort is to deliver a fully validated facility, utilities, HVAC, and process systems, as per GMP requirements. This process can be lengthy and onerous, and a product cannot be manufactured until it is completed.

In an expedited EPCMV project, there are several key elements to ensure the timely and robust delivery of the CQV effort. The most important point is to involve the validation experts as early in the project as possible. This allows them to verify requirements, understand or help develop a CQV strategy and project approach, and establish an on-site presence that will expedite downstream execution efforts.

-

read more

The beginning of a validation life cycle is the generation of user requirements (URS), a foundational document crucial for a smooth quality risk management (QRM) and CQV process. The URSs identify and document product process and knowledge, which are the critical parameters that must be validated in the end. More often than one would imagine, URSs are not developed on time, which ultimately leads to the prolonging of qualification execution. Involving the CQV team early allows validation experts to work with the proper subject matter experts to develop these important documents.

There is a multitude of CQV guidance available, and every approach is a little different. The sooner an approach can be developed and implemented via a validation master plan (VMP) the better. The EPCMV validation team can develop the approach and VMP.

Establishing URSs, conducting risk assessments, and writing the VMP lay the foundation for the project. Now that the validation team is involved, they can get an early start on the development of testing protocols. Having been involved from the start, they will have stronger systems knowledge and be able to generate better protocols, reducing review and approval times.

Involving validation as part of the EPCMV team early and often in the project is the key to success, especially in the case of an expedited project. It allows for greater CQV planning earlier and this results in time-saving activity later in the process.

Trust your EPCMV partner

To abide by quicker timeframes, you should pick a tried and trusted design, construction management, and CQV partner. Here are some things to consider when looking for an EPCMV vendor:

-

Cultural alignment

-

Agile practices

-

Experience working remotely

Expediting a fast-track facility requires working outside of traditional office hours including nights, weekends, and holidays, with a team that trusts each other and believes in the same end-goal (in this case, developing a process to make an effective vaccine as quickly and safely as possible). Without a cohesive team, you risk cost, schedule, quality, and, ultimately, the project.