Table of Contents

The challenge

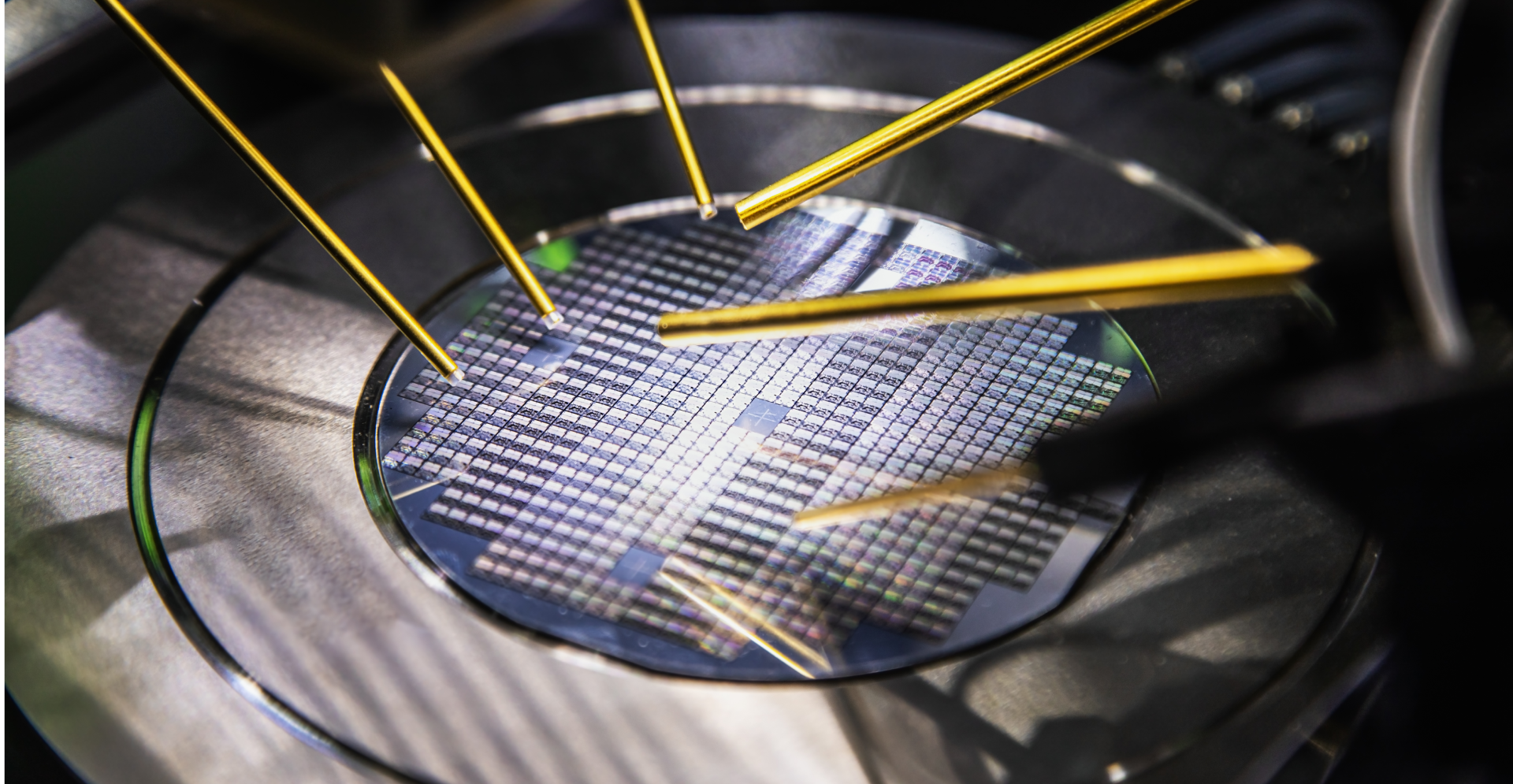

Our client needed to expand wafer output at a facility in one of their USA sites.

850,000+

A global leader in the semiconductor industry was looking to fit out a newly built FAB facility to continue the advancement of their wafer fabrication output to support the automative industry. As a leader in the space deploying the world's most advanced memory technology, they partnered with Arcadis to execute the design and construction of a semiconductor FAB facility tool install program.

The solution

Designing and implementing a full turnkey solution through procurement, construction management, project completion qualification, and handover to the client.

90,000

As part of this effort, Arcadis offered a turnkey solution model of engineering, procurement, construction management, and project management (EPCM) to act as a single partner who could execute all aspects of the client’s needs. Arcadis worked with the client to identify LLM (Long Lead Material) through the design lifecycle and went out to the market to secure equipment and materials to deliver the project on schedule and secure cost certainty in a volatile market. This comprehensive design focused on expediting the program and reducing inefficiencies. Arcadis also pre-qualified trade partners to confirm that the project had the best qualified team to execute the onsite work. With the implementation of the Arcadis lean tool install design packages, as well as our safety and project management systems, we met our client’s end goal.

The impact

The facility’s production volume expanded to increase the wafer output and keep up with the ever-challenging microelectronic market.

140

This implementation has increased capacity of wafer output and is producing more microchips to keep up with the demand of the automative industry, empowering the Arcadis client to be an industry leader in the semiconductor market. Arcadis executed on the construction of this project while achieving a best-in-class TRIR (Total Recordable Incident Rate) as part of the safety program throughout the lifecycle of the project.

Not done reading?

This also might be interesting for you

- Related Projects

- Related Insights

- Related Blogs